Mobile Suction Systems – Vacuum Loaders

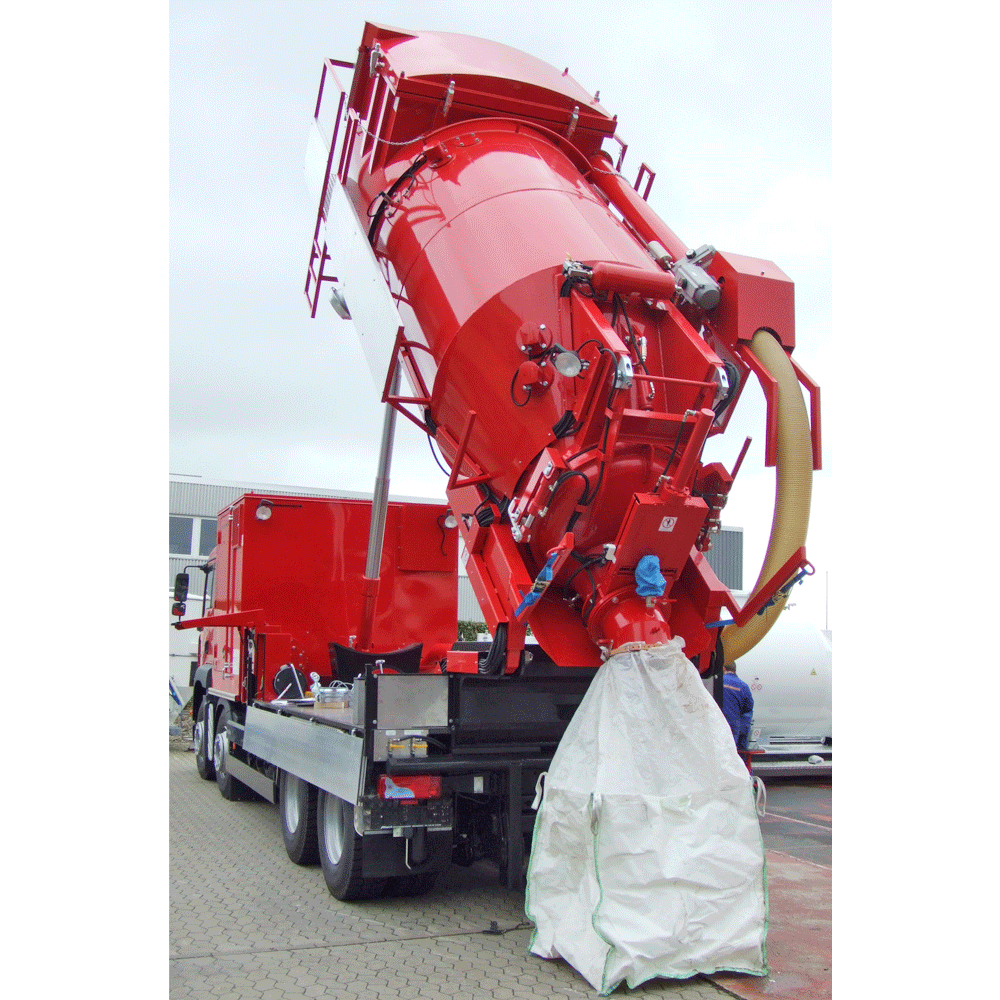

BlowVac

The top of the line model among truck mounted vacuum systems.

Professional industrial vacuum cleaning for bulk material applications. Designed for the extraction of dry, humid or liquid materials with high suction power over long distances.

Different discharge devices adapted for various applications. Blowing device for pressure discharge of dry bulk materials or to blow gravel onto roofs or into silos. Explosion protection systems for extraction of explosive types of dust.

Performance: Different pump sizes with airflow from 2100 m³/h to 10000 m²/h. Suction power 500 mbar or 900 mbar. Engine power: 37 kW to 340 kW. Driven by electric motor, Diesel engine or by the truck engine.

Special models with explosion protection systems according to Atex. Safe solutions from the explosion protection specialist for explosive types of dust. No fig-leaf solution just with grounding control, but sophisticated explosion protection with pressure relief systems, explosion suppression systems, flame absorbers and explosion isolation systems. All explosion protection systems are certified as protection systems according to Atex EX II 1D.

BlowVac units are used:

- to vacuum extract industrial types of dust at high suction rates, e.g. in cement plants, steel plants, power plants, chemical plants

- to vacuum extract blasting material used for maintenance work at bridges or buildings

- to vacuum extract gravel from roofs and to blow fresh gravel onto roofs.

- to fill bulk material into silos with the pressure discharge system

- to overcome silo blockages

- to vacuum extract sand or soil when repairing under-ground gas pipes, electric cables or telephone lines

- to pressure discharge sand to fill ditches for pipes or cables

- to vacuum extract soil in communities, e.g. to replace soil around trees

- to vacuum extract insulation material when renovating houses and blow granular insulation material into houses

- to extract grit material in shipyards

- to empty out catch pits from sand and sludge

- to clean and maintain railway lines in industrial compounds and to free rail grooves from accumulated dust

BlowVac units can be mounted on trailers, trucks and hook-frames.

Four different types, each with different collection capacities and pump sizes:

BlowVac Conic:

Conical collection container for tipping discharge or for pressure discharge of the suction material into silos

BlowVac SL:

The traditional vacuum loader with maximum collection capacity. Optimised for pressure discharge with high blowing discharge rate

BlowVac BigBag:

The All-rounder. Fills the suction material into BigBags, tipping discharge into open containers, pressure discharge into silos with the blowing device

VacTruck – one system, three models

Available as VacTruck 3700-80, 6000-50 and 6000-80. Distinguishes itself by its compact and straight-forward design. Can be equipped with a discharge system for BigBags. Collection capacity up to 15000 l.

VacTrailer

Industrial vacuum cleaning and conveying units for professional use.

Designed for the extraction of dry and humid suction material, as well as for dry explosive bulk material and for pyrophoric catalyst handling.

High-tech filter systems for asbestos and other dangerous materials.

Discharge of the suction material into BigBags, drums, FlowBins and open containers.